How can we gain more insight into the human heart and other organs to study disease progression or direct therapeutic effects? The answer lies in miniaturized lab-on-a-chip devices that mimic and isolate the organ of interest. We reported how scientists at Boston University created a heart-on-a-chip platform to investigate the response of cardiac microtissues under prescribed mechanical loading and pacing. As the next step, the scientists have now combined Two-Photon Polymerization (2PP) with cell biology to create a fully functional heart chamber that pumps fluids through its system, driven by the contraction of heart muscle cells.

Next step towards a 3D printed heart-on-a-chip platform for cardiac research

Our hearts are truly powerful organs. On average, it beats about 100,000 times per day, pumping more than 7,000 liters of blood through our system, while each contraction generates enough force to propel blood up to 9 meters in a fully dilated blood vessel. Although research and medicine have come a long way in understanding this busy organ, cardiovascular diseases remain a major concern and are the leading cause of death worldwide. In this context, in vitro models of the heart are valuable tools to advance the understanding of cardiac physiology, investigate disease mechanisms, develop drugs, and evaluate drug safety. They provide a controlled and accessible platform for cardiac research and contribute to the improvement of cardiovascular health.

Miniaturized in vitro human heart model

An interdisciplinary research team at Boston University has recently developed a miniaturized in vitro model of a human heart chamber combined with valves that mimics cardiac output and generates rectified flow. Like a real heart, the microscale replica requires no external energy source, but is powered by heart muscle cells (cardiomyocytes) that can pump fluids through the system. The scientists used Nanoscribe's two-photon polymerization technology to 3D print this heart pump, including the valves to ensure unidirectional flow in the system.

Two-Photon Polymerization of biocompatible cell scaffolds

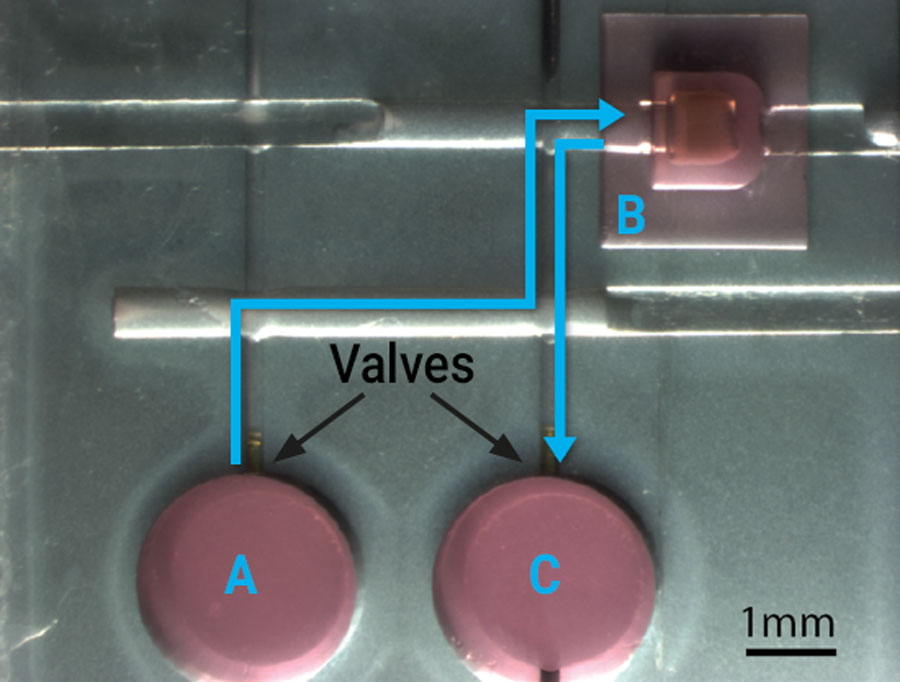

The platform for the artificial heart on a chip consists of a microfluidic PDMS chip with a supply well, the heart pump chamber and a high-pressure output well. Embedded in the heart pump chamber is the key element of the platform: a 3D printed cylindrical scaffold made from the biocompatible photoresin IP-S. This scaffold is freely deformable in the axial direction, allowing it to pump fluids through the system. Once the scaffold is attached to the microfluidic system, human induced pluripotent stem cells (hiPSC-CM) are seeded onto the scaffold. Driven by the contractile force of these cells, the cylindrical scaffold generates a pressure gradient that moves fluids in the microfluidic channels. Multiple design iterations and empirical testing were necessary to arrive at a sophisticated scaffold design that can withstand significant tissue compaction and allow flow to be generated without collapsing.

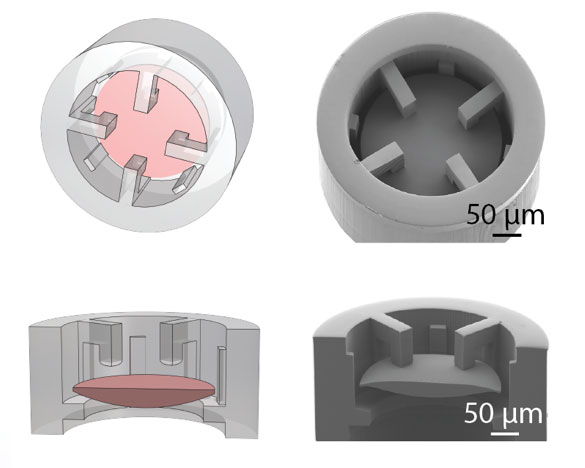

3D-Microfabrication of valves for unidirectional flow

Another challenge the scientists faced was the development of a valve that ensures a rectified flow to the output channel. Like a natural heart, the contractions of the scaffold pump result in an oscillating flow. A micro-engineered valve was developed that rectifies the flow and ensures that fluid is constantly pumped from the supply well into the heart pump chamber and from there into the high-pressure output well. This once again demonstrates 2PP's strength as an additive manufacturing technology: design iterations can be made easily and printed quickly for testing. The scientists tested several designs and found that a valve with a free-moving, convex plate that swings back and forth between the open and closed states was the most efficient.

Significance of this biochip-centric project

The Boston University-led interdisciplinary team's findings pave the way for studying disease progression in unprecedented ways and could lead to a whole new generation of chip-based versions of other organs, from lungs to kidneys. As a BICO company, Nanoscribe anticipated the great potential of 2PP-based 3D Microfabrication for bio- and life-science applications. With Quantum X bio, Nanoscribe offers the world's most accurate 3D bioprinter.

Would you like even more insight into this exciting project? Then read the scientific publication here: Engineering a living cardiac pump on a chip using high-precision fabrication

The complete publication and further scientific publications on hundreds of research projects can be found in a powerful database with an underpinned keyword search in the Premium Resources section. Register for free and gain insights into the potential of Nanoscribe’s 3D Microfabrication technology for innovative applications and fundamental innovations in many areas.

Video information

Video 1: Real-time video of the cardiac chamber in action. The platform pumps fluids through the system due to contractions of the cultured cardiomyocytes. Video: Michas et al., Sci. Adv. 8, 16, (2022), Boston University.

Video 2: A suspension valve in action. The convex plate allows the fluid to travel in one direction only.

Michas et al., Sci. Adv. 8, 16, (2022), Boston University.