Quantum X systems

boost your throughput up to 100 times

Maximize your productivity

with proprietary technologies and industry-standard solutions

High-precision 3D printing is no longer a slow business. Rapid prototyping enables exceptionally short design iteration cycles. And direct printing of 2.5D and 3D structures using high-performance technologies and wafer-level batch processing enables small to high volume fabrication of parts with submicron features. And best of all, with Nanoscribe, you no longer have to compromise on manufacturing quality.

Scientific microfabrication

- Industry-proven upright platform for wafer-scale batch processing and Dip-in-Laser Lithography (DiLL)

- 200 typical mesoscale structures printable overnight

- Print volumes up to 30 cm³ in a single run with the XLF Print Set

- 2GL® Grayscale Lithography for rapid and accurate surface patterning

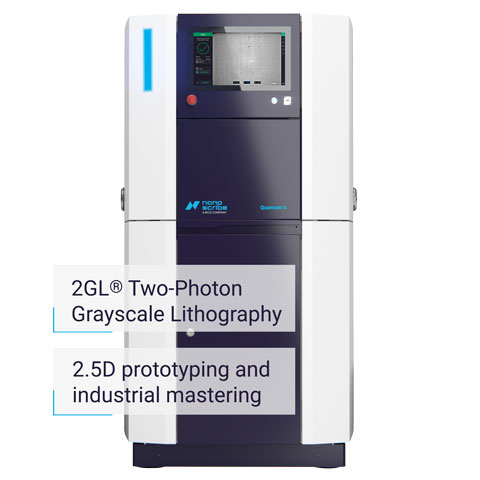

Industrial mastering

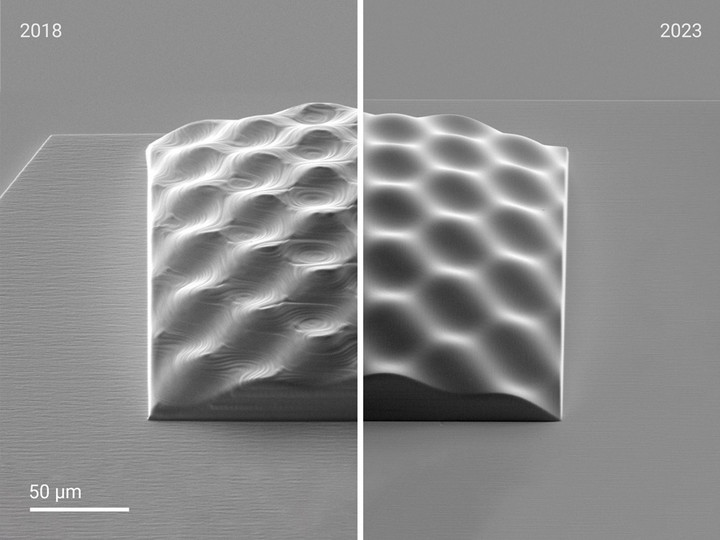

- Two-Photon Grayscale Lithography (2GL®) for prototyping and mastering by high-speed single voxel tuning

- Up to 100 times higher throughput

- Industry-proven upright platform for wafer-scale batch processing

- Tilt compensation for smooth surfaces and truly seamless structures with 2GL® stitching

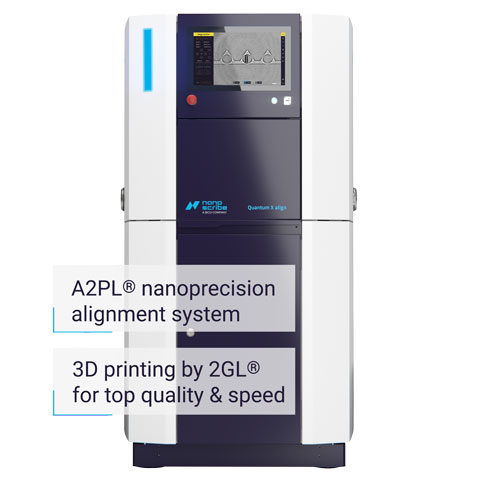

Industrial manufacturing

- 3D printing by 2GL® Two-Photon Grayscale Lithography providing superior quality at unrivaled speed

- Up to 60 times higher throughput

- Aligned 2-Photon Lithography A2PL® for nanoprecision alignment on optical fibers and photonic chips

- 3D alignment detection accuracy and feature size control down to 100 nm

Dr. Lucas Meza, Assistant Professor, University of Washington

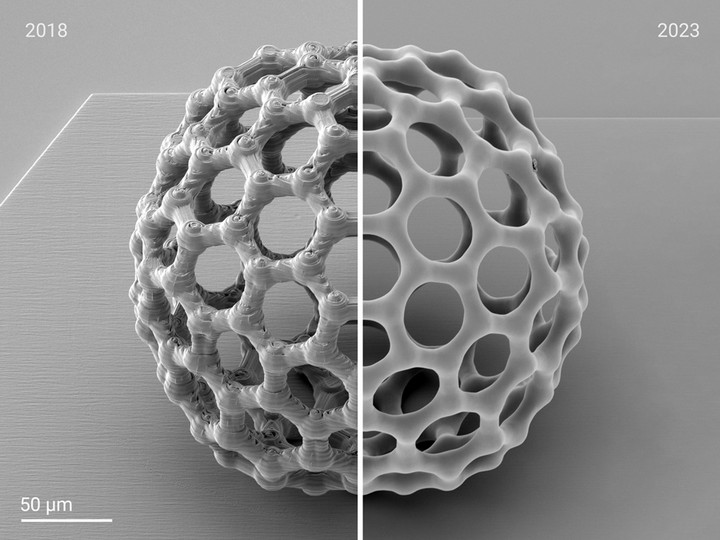

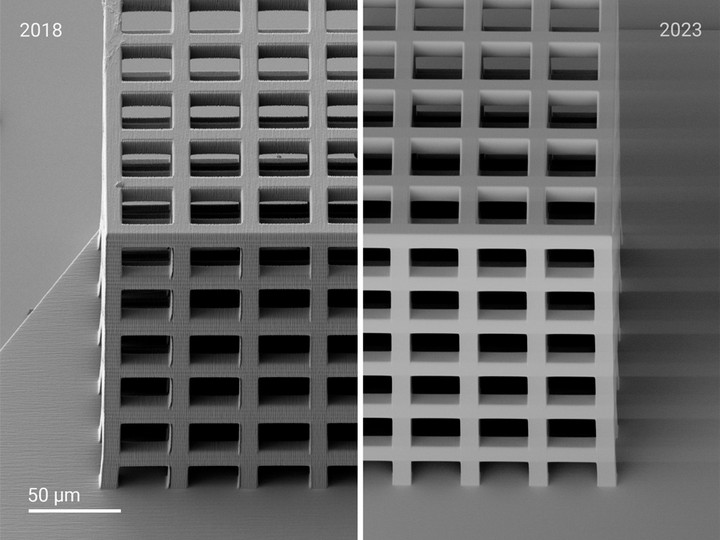

"Testing the Quantum X system at Sandia's CINT facility was eye-opening. The print time of 24 hours for each structure with Photonic Professional GT has been cut to 13 minutes and the quality improved."

Choose from specialized products

or let us customize a Quantum X shape for your needs

Nanoscribe's productivity technologies and solutions can greatly streamline your nano- and microfabrication tasks, whether you are manufacturing mechanical parts, engaged in 3D bioprinting, or performing aligned 3D printing with nanoprecision on optical fibers or photonic chips.

Quantum X product line

Discover the new Quantum X platform with its application-focused, high-resolution production models.

Let us prove excellence

Challenge us to prove the feasibility of your project ideas and demonstrate the superiority of our technology.

Any questions left?

Contact us, get answers from our experts and find out more about our cutting-edge technology.

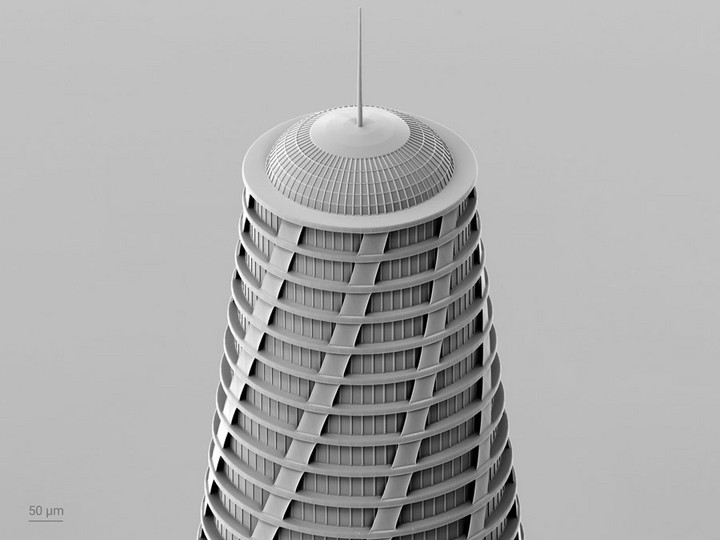

Micro Miracles

A magical level of detail and precision!

This kind of project is definitely a rare opportunity. Something outside of our daily business – and yet so exciting and well-suited to our latest, state of the art 3D Microfabrication technology.

Samsung Semiconductor asked us to 3D print unique models for an extraordinary promotional video to showcase the smallest technological wonders of the microscale world that are becoming increasingly important in many areas of life.

At first, they were unsure if this was even possible. But see for yourself, we printed it for real. We recommend the behind-the-scenes video, which introduces the creators and the video production step by step. It also shows how amazingly fast and easy such complex 3D models can be printed.

Ready to be surprised?

The maker of Micro Miracles

Want to take a look behind the scenes?

Ready for high-precision 3D printing

with superior quality at unrivaled speed?

From a teenager with a game console to a detailed 56-story skyscraper, all 8 the video's sculptural structures ultimately showcase the capabilities of Nanoscribe's high-precision 3D printing technology in the fields of scientific and industrial microsystems. With this technology, any conceivable or functional 3D design for applications such as microoptics and integrated photonics, microfluidics, micromechanics, and micro-electro-mechanical systems can be realized in the nano- and microscale world.

Quantum X systems

print fast AND with great quality

Make your ideas a reality

and go beyond the previous limits of microfabrication

Nanoscribe is pushing the limits of print quality, precision, speed and ease-of-use with technological advances and state-of-the-art software. Quantum X is a radically new platform for Two-Photon Polymerization-based microfabrication, bringing new features to the most challenging microfabrication tasks.

Technological advances in brief

- Radically redesigned upright platform for comfortable operation with Dip-in-Laser Lithography (DiLL) technology

- Wafer-level batch processing up to 8" wafers

- Unrivaled versatility, precision and speed, e.g. 200 millimeter-scale structures printable overnight

- Four Print Sets for the highest precision at different scales from nano to macro

- Automatic calibration of laser power and positioning system, and fully automated job execution

- Future-proof modular platform, ideal for specific applications and multi-user facilities

Key technical feature options

- Two-Photon Grayscale Lithography 2GL®

- Aligned 2-Photon Lithography A2PL® for automatically aligned 3D printing on microchips and optical fibers with nanoprecision

- Bioprinting chamber controls temperature and humidity with HEPA-filtered CO2/air flow

- Multiple interface detection methods for significantly enhanced print accuracy, quality and substrate flexibility

Prof. Dr. Harald Giessen, University of Stuttgart, Quantum X customer

"My first print job worked flawlessly and the structure is stunningly good, if not to say sensational. I have never seen anything like this before."

Intuitive workflow and superior usability

with performance enhancing software

The Quantum X systems are designed with your convenience and a streamlined printing process in mind. The system and software usability, and straightforward workflow are second to none, making microfabrication more powerful and accessible than ever before.

Aligned 3D printing

Compose and automatically align your prints efficiently with nanoPrintX and its scene graph-based features to unlock A2PL®.

2GL grayscale printing

Easily create your 2GL print project with GrayScribeX and use voxel modulation for smooth optical quality surfaces.

Full remote control

Have full remote control over printing projects with nanoConnectX, perfect for multi-user and multi-printer scenarios.

Control at your fingertips

The touchscreen provides easy access to information and controls, plus a shared job queue and live-view cameras.

Tap to align your prints

Print complex structures aligned to patterned surfaces or specific positions with a simple gesture.

Virtual navigation camera

Benefit from automatic collision prevention when using specialized substrates or the bioprinting chamber.

Quantum X systems

ready for industry and research labs

Industrial and laboratory standards are critical to the effective operation of microfabrication systems in real-world professional environments. To ensure precision and process reliability, Quantum X systems meet these standards and offer industrial-grade features such as

- Industrial housing designed for modularity

- Wafer-scale batch processing

- Granite base and vibration damping for high mechanical & thermal stability

- Automatic self-calibration for accurate laser power control and positioning

- Automatic tilt compensation and 2GL stitching for flawless, seamless structures across multiple square millimeters

- Industrial and laboratory standard substrate sizes and types

- ISO standards, factory and site acceptance tests